Could improvements in aerodynamic quality, such as reducing drag or modifying wing designs, make Electric Aircraft (EA) viable? Our analysis shows that a 40% increase in the lift-to-drag ratio of a regional turboprop can reduce the batteries specific energy required to achieve cost parity with traditional aircraft from around 3,000 Wh/kg to 1,000 Wh/kg (still unrealistic, but much closer to reality). On its own aerodynamics won’t make currently available Li-ion-powered EA a viable competitor for internal combustion aircraft (ICA), but it will reduce the cost gap between the EA and ICA down to just ~40%. The reduced cost gap could be potentially bridged by improvement in aircraft mass and a future decrease in electricity prices. So, improved aerodynamics is an important enabler for EAs. Could it be achieved? Let’s find out.

Impact of increased aerodynamic quality on cost

In a previous post, we discussed how various factors affect the cost per passenger-kilometer (C). Using the Breguet equation, we demonstrated that the cost is inversely related to the aerodynamic quality (or lift-to-drag ratio q) of the aircraft:

Let's take a closer look at the definition of q. The aerodynamic force acting upon an aircraft is made up of two components: lift force (L), which is perpendicular to the direction of travel, and drag force (D), which opposes the direction of travel. As an airplane flies horizontally, the lift force points upward, giving it its fitting name.

Both lift and drag forces are roughly proportional to the air density (ρ), the square of the aircraft's speed (V), and the surface area of the aircraft (S), also called the wet surface. This name originates from the idea that if the aircraft were covered in a thin film of liquid, such as water, the liquid would "wet" the exposed surfaces that are in contact with the airstream. By measuring the wetted surface area, engineers can calculate the aircraft's lift, drag, and other aerodynamic properties:

The dimensionless proportionality coefficients in each equation are called the lift coefficient CL and the drag CD coefficient. The lift-to-drag ratio is then:

Interestingly, lift and drag coefficients show little dependence on airspeed and density, as long as the speed is not too low (during takeoff) or too high (approaching the speed of sound). So, these coefficients are primarily defined by the shape of the aircraft. For this discussion, we won't delve into the variability of these coefficients during takeoff or landing, focusing instead on a horizontal cruise.

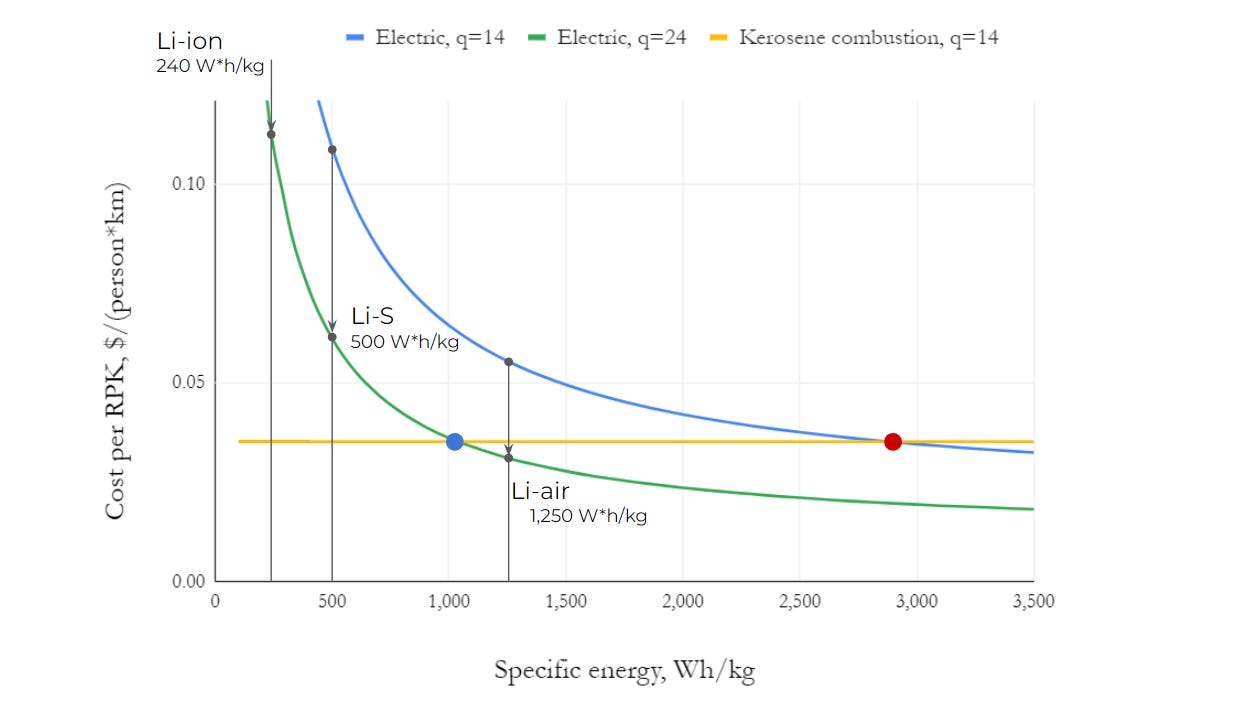

A higher value of q means less power is needed to keep the aircraft in the air. For example, the DHC-8 Q400, which we previously used as a model for a regional aircraft, has a q value of 14. As equation (1) indicates, increasing q to, say, 24, could reduce the cost per RPK by almost 40%. We demonstrate this through a C vs. e plot, where C is shown as a decreasing function of battery specific energy e (blue curve, q=14). Similar to earlier, we compare the cost of electric propulsion (blue curve) with the cost of kerosene propulsion (yellow line). We've now added a third curve, representing the cost function for an improved electric aircraft with q=24 (green curve):

We can see that a 40% improvement in aerodynamic quality doesn't allow EA powered by lithium-ion (Li-ion) or lithium-sulfur (Li-S) batteries to outperform kerosene-powered ICA. Within the 240-500 Wh/kg range, the green curve consistently stays above the yellow line. However, advancements in aerodynamics can significantly decrease the energy density requirements for EAs to reach cost parity with ICAs—by almost three times (blue dot on the plot). A 40% increase in aerodynamic efficiency could enable EAs powered by batteries with an energy density greater than 1,000 Wh/kg, such as lithium-air batteries, to compete, provided they are durable enough.

Currently, even the most advanced Li-ion batteries (like the 500 Wh/kg lab prototype from Amprius) would result in a cost per revenue passenger kilometer (RPK) that's at least 43% higher than ICAs (even with an optimistic assumption, that we can make them cheaply and durable enough). It's important to note that the green line on our graph already takes into account the higher efficiency of electric motors compared to ICA turbines.

So, to bridge this cost gap between ICA and EA, we need to find additional efficiencies elsewhere. Is this even theoretically possible? One way to achieve this kind of cost improvement would be to reduce the aircraft's weight by 43% or alternatively decrease electricity, maintenance, and purchasing costs by the same percentage.

For instance, if Elon Musk's vision of using batteries as structural elements become a reality, it could lead to a reduction in airframe weight efficiency (m/M), resulting in a comparative weight advantage for EAs over ICAs.

Now, let's circle back to the lift-to-drag ratio and discuss how it could be improved.

Сheaper should not mean slower

One common approach to improving aerodynamic efficiency q is to increase the wingspan. This enhancement raises both lift and drag coefficients, bringing the lift-to-drag ratio closer to that of the wing (above 30) rather than the fuselage (below 5). Consider the Lockheed U2, for example, which boasts a q of 25.6. Gliders can achieve even better lift-to-drag ratios, soaring up to 70.

So why do airlines opt for aircraft with q=14 (regional) or, at most, q=19 (long-haul) when a q=24 would save them fuel? Indeed, from equation (1), it follows that a higher q translates to lower fuel (or energy) costs:

The main reason lies in the low speed of typical high-q aircraft. As q increases—due to a larger wingspan—the aircraft's surface area S also expands, leading to a decreased cruise speed V.

Emerging blended wing body aircraft designs aim for a q of 20-25 by reducing some drag while maintaining a moderate lift. This allows them to achieve a streamlined aerodynamic design without sacrificing too much speed. Two other energy-saving technologies gaining attention, which don't compromise flight speed, are high aspect ratio wings and distributed propulsion.

(Un)fair competition?

In summary, if we want to make fully electric aircraft viable for regional flights and beyond, we'll need to achieve significant improvements in aerodynamic efficiency. However, it's crucial to note that not all optimizations are exclusive to electric aircraft, suggesting that there might be competition between EAs and ICA using, for example, eco-friendly fuels if both aircraft types benefit from the same increased lift-to-drag ratio. Enhancing lift-to-drag will make both types of aircraft more energy- and cost-efficient but won't necessarily give one an advantage over the other. The plot below demonstrates this point: the cost-parity point remains at approximately 3,000 Wh/kg if both EA and ICA are optimized in the same way:

But are there lift-to-drag improvements that can be implemented exclusively for EAs and not ICAs? One such example is distributed propulsion, which involves using multiple small motors instead of one or two large ones. Distributed propulsion allows for higher airflow speed over the wing compared to the fuselage (for the latter, the airflow speed would simply be the aircraft's speed), enabling the aerodynamically efficient wing to play a more prominent role in lift than the less efficient fuselage. This is why many electric vertical takeoff and landing (eVTOL) aircraft and proposed light electric aircraft designs feature distributed propulsion.

Distributed propulsion is, in theory, possible with internal combustion aircraft, but it's more practical with electric-powered propellers. Having numerous combustion-powered propellers would likely result in increased maintenance costs, which could outweigh the gains in aerodynamic efficiency. Electric-powered propellers, on the other hand, have fewer moving parts and are therefore more cost-effective to operate.

While improving aerodynamic efficiency alone doesn't solve the problem of reducing electric aircraft costs compared to conventional aircraft, it brings us closer to cost parity. Combined with other advancements, this makes the prospect of EAs much more realistic. To learn about what these improvements might be and how they can be achieved, stay tuned for our upcoming articles.

What will make electric aviation affordable? Tidal Wave on Substack, January 17, 2023

Fluid-dynamic drag. A textbook by Sighard F. Hoerner, 1965

Bombardier Q Series technical specifications. Bombardier Inc, 2017

Amprius announced 500 Wh/kg LiIon battery, how is this possible? Let's find out! Tidal Wave on Substack, April 12, 2023

Tesla 2023 Investor Day. YouTube live recording. March 1, 2023

Cruise Performance Optimization of the Airbus A320 through Flap Morphing. Martin Orlita and Roelof Vos at 17th AIAA Aviation Technology, Integration, and Operations Conference, June 2017

Effect of fuselage diameter on aerodynamic characteristics for straight wing at low and high aspect ratio. H. C. Laia and N. M. Kamaruddin at International Conference on Aerospace and Mechanical Engineering, November 2017

Unlimited horizons: design and development of the U-2. Peter W. Merlin, NASA aeronautics book series, 2015

Eta aircraft description. Flugtechnik & Leightbau, 2003

Blended Wing Body – A potential new aircraft design. NASA, April 22, 2008

NASA picks Boeing’s Transonic Truss-Based Wing for Sustainable Flight Demonstrator project. Ginger Gardiner for Composites World, January 19, 2023

Drag Reduction Through Distributed Electric Propulsion. Alex M. Stoll et al. at 14th AIAA Aviation Technology, Integration, and Operations Conference, June 2014

Distributed Electric Propulsion. Mark D. Moore YouTube interview for NASA Langley Research Center. October 22, 2014