[Blog] Amprius announced 500 Wh/kg LiIon battery, how is this possible? Let's find out!

If you keep up with the news in the world of batteries and electric vehicles, you may have heard about Amprius' recent announcement regarding the creation of a Li-ion battery with a specific energy of 500 Wh/kg. Amprius is a reputable publicly traded company founded by esteemed Stanford professor Yi Cui, with Nobel Laureate Steven Chu serving on its Board of Directors. As of October 2022, the company was working on commercialising technology that would enable the mass production of 450 Wh/kg batteries, which would already be a significant advancement for the EV industry, where the current standard is in the range of 240-260 Wh/kg. However, just six months later, a 500 Wh/kg battery seems not only possible but almost certain.

How is this possible? Is this a sudden leap forward, or a gradual progression towards more advanced batteries? While commercial secrets may obscure some details, much can still be gleaned from the open sources. Let’s find out.

Amprius' achievements are positioned as being due to the silicon anode technology developed by professor Cui's group pioneering works (relevant papers can be found here and here). Silicon itself is capable of providing a huge capacity of the anode - theoretically up to 4,200 mAh/g, compared to 339 mAh/g for graphite anode used in Tesla batteries. This superior capacity is possible if the anode consisted of pure silicon, absorbed lithium in a stoichiometric ratio (4.4 lithium atoms to 1 silicon atom) during charging, and completely gave it away during discharge, again becoming pure silicon.

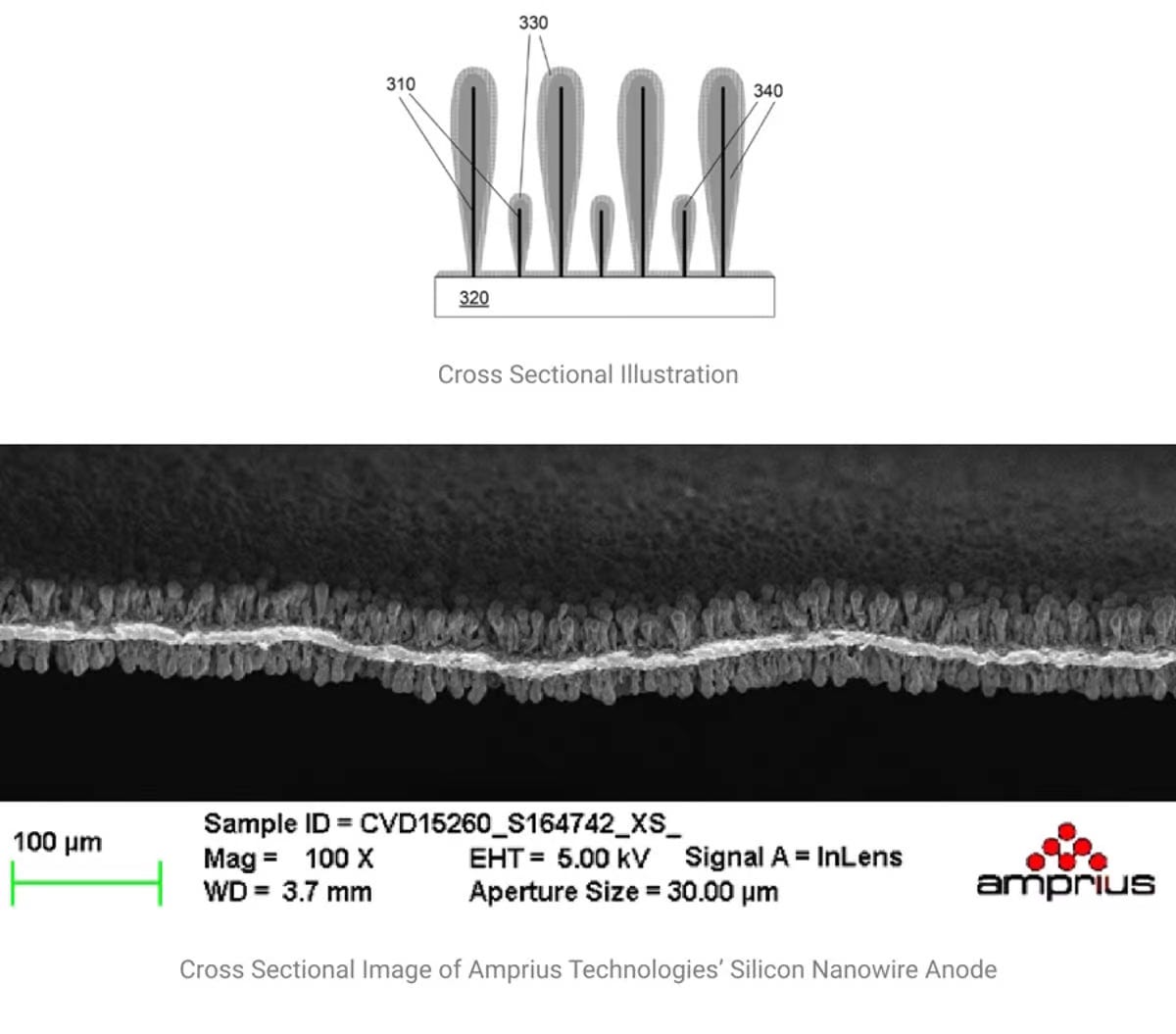

In reality, Si is always not the only material of the anode. In particular, Amprius’ anode consists of silicon nanowires, which themselves are attached to a metal substrate (most probably stainless steel). The substrate is needed for the rigidity of the anode, as well as for the current collection. The nanowires are not destroyed during the charge-discharge process, ensuring battery longevity, which would not be the case with a solid silicon anode. It is difficult to say precisely what fraction of the mass of the anode will be due to the current collector, but an order of magnitude estimate can be made based on the description of the anode in the company's patent, and microphotographs presented, for example, at 2020 NASA Battery Industry Day. According to our estimates, the proportion of silicon is in the range of 10-20%. Even with these numbers, silicon anodes offer impressively high practical limits over the anode capacity at 380-690 mAh/g. Note that those are the upper limits because full lithiation and delithiation of the anode are never possible.

With such high performance, the specific energy is limited by the capacity of the cathode rather than the anode. Back in October 2022, according to the company's reports, we could conclude that it was LiCoO2 (aka LCO) cathode, which has a practical capacity limit of about 155 mAh/g.

To translate anode and cathode capacities into the upper limit of the assembly’s specific energy, we adopted the conventional method, essentially a thorough mass accounting of all battery components (it is well narrated, for example, here and here). The nominal voltage needed for our calculations can be taken from Amprius’ most recent test report: it is equal to 3.45V. The results are visualized in the plot below:

To summarise, with the LCO cathode (blue curve), and Si nanowire presented before it would be hard to achieve specific energy higher than 450 Wh/kg. The steep slope of the specific energy as a function of Si content in the anode demonstrates, that with a given Si density on the anode, the battery performance is limited by the cathode. To achieve the reported 500 Wh/kg with LCO, Amprius would have to construct anodes with unbelievable Si participation above 50% by mass. We believe, that instead, the company moved to a more advanced cathode (red curve), like NMC (LiNi(x)Mn(y)Co(z)O2, x+y+z=1), for which there are reports of capacity beyond 180 mAh/g in laboratory conditions.

“The 500 Wh/kg battery platform” that we can see in Amprius’ last announcement means a combination of a Si anode and an advanced cathode in one device, that allows exploring the higher limits of specific energy. As we can see from the independent technology test protocol, which included only two charge-discharge cycles, the platform needs more tests and adjustments to find the optimal spot in specific energy vs. durability tradeoff. With the current state of technology, the platform could soon be demonstrated in applications where only a few dozen charge-discharge cycles are needed, such as powering a high-altitude solar plane, where Li-S and Si-anode Li-ion batteries already performed well.

But nonetheless, we look forward to get more news and details about the Amprius’ technology and are very excited that this might be the harbinger of a long-lasting commercial battery with more than 500 Wh/kg (which we believe will make electric aviation much more viable, read more about our estimates in this blog soon)!